Our Elk Valley Water Quality Plan Progress Update includes information about our existing and planned water treatment and data showing the stabilization and reduction of the selenium trend.

Suite 3300, Bentall 5

550 Burrard Street

Vancouver, B.C.

Teck operates four steelmaking coal mines in the Elk Valley of British Columbia which employ over 4,000 people. We raise our families in the valley, fish and swim in the river and care deeply about ensuring the environment is protected. That’s why we’re focused on responsible mining and ensuring that the environment and water quality are maintained in the valley now and for generations to come.

Our Elk Valley Water Quality Plan Progress Update includes information about our existing and planned water treatment and data showing the stabilization and reduction of the selenium trend.

The following factsheet uses data from the Water Quality Portal (WQP) to compare selenium concentrations found in fish in the Kootenai River and Koocanusa Reservoir against US Environmental Protection Agency protective criterion.

The WQP is a cooperative service sponsored by the United States Geological Survey (USGS), the Environmental Protection Agency (EPA), and the National Water Quality Monitoring Council.

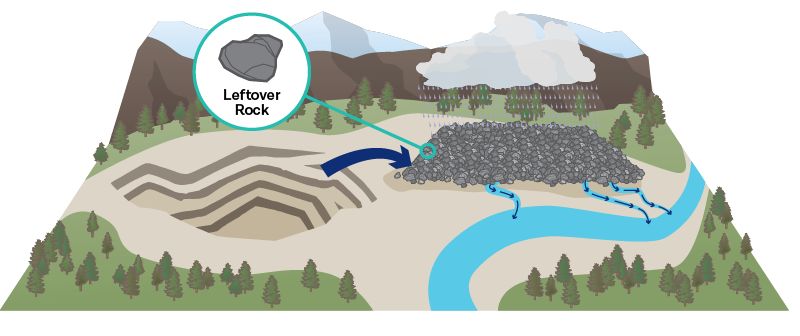

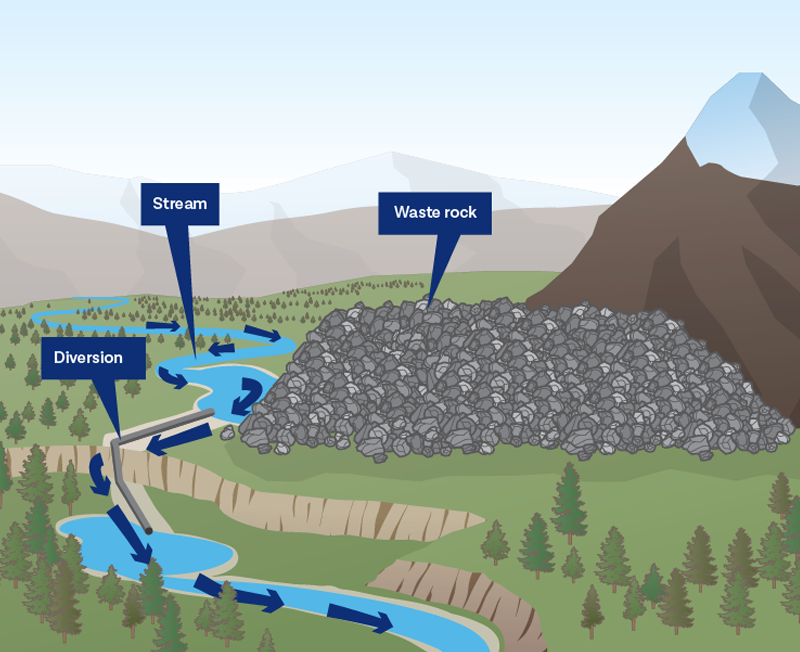

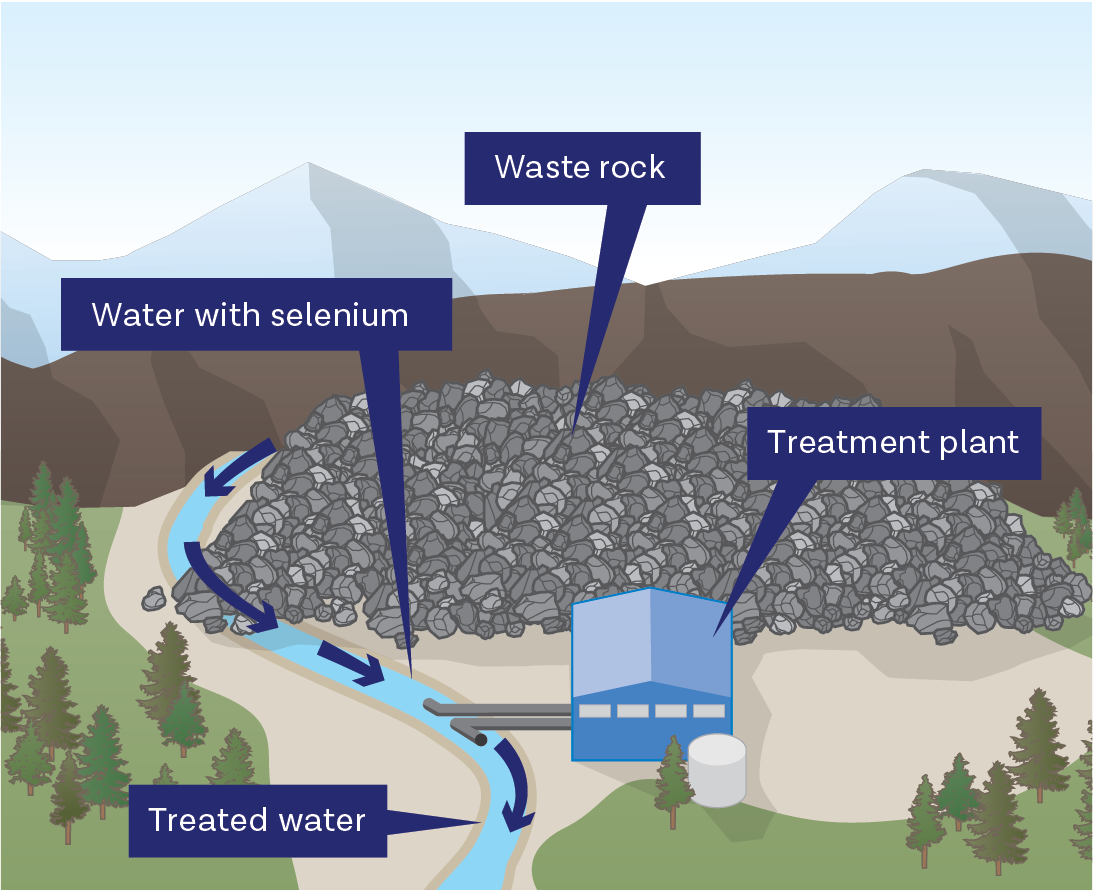

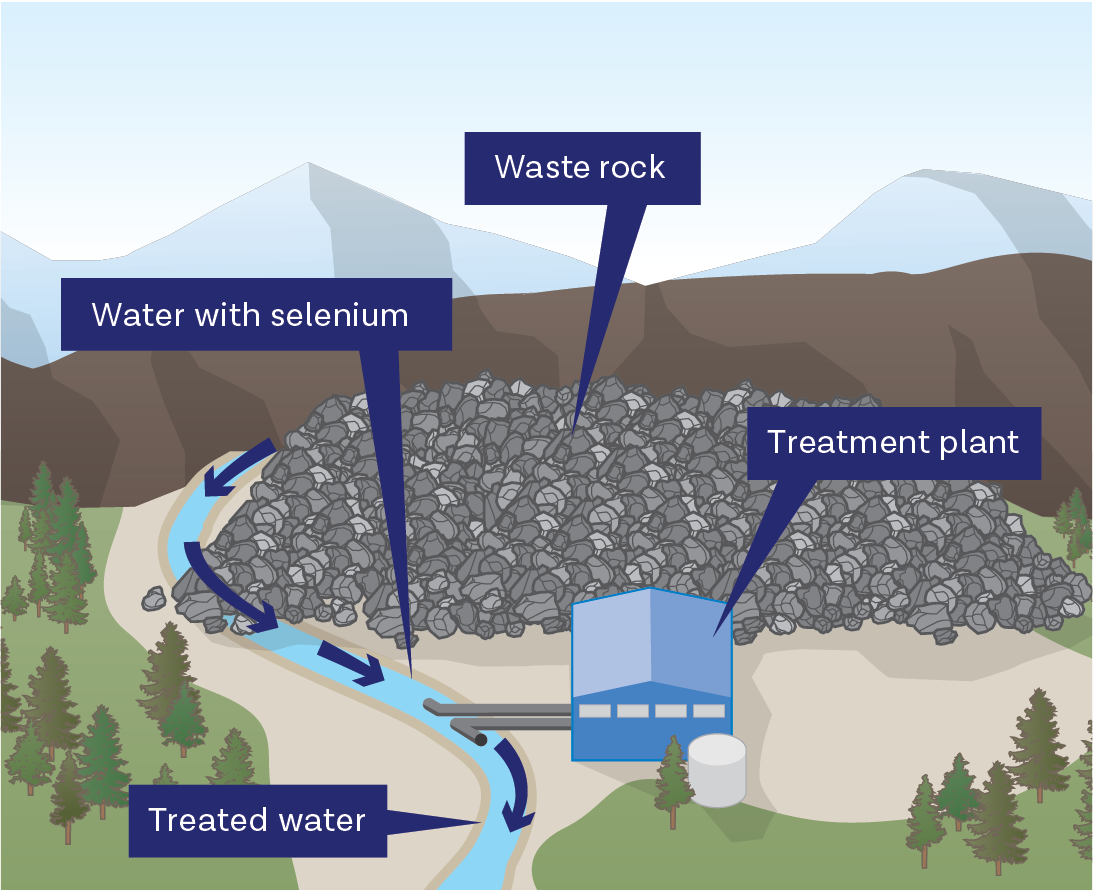

Water quality challenges in the Elk Valley are connected to the long history of mining in the region. The mining process generates large quantities of leftover rock that contains naturally-occurring substances such as selenium, an element that is essential for human and animal health in small amounts. Water from both precipitation and runoff flows through these rock piles and carries selenium and other substances, such as nitrate, into the local watershed. If present in high enough concentrations in the watershed, these substances can adversely affect aquatic health.

Water quality challenges in the Elk Valley are connected to the long history of mining in the region. The mining process generates large quantities of leftover rock that contains naturally-occurring substances such as selenium, an element that is essential for human and animal health in small amounts. Water from both precipitation and runoff flows through these rock piles and carries selenium and other substances, such as nitrate, into the local watershed. If present in high enough concentrations in the watershed, these substances can adversely affect aquatic health.

In 2013, in consultation with the Government of BC, the Ktunaxa Nation, scientists, and local communities, Teck developed the Elk Valley Water Quality Plan, which was approved by the Provincial Government in 2014. This is a long-term plan with the goal of stabilizing and reversing the trend of selenium, calcite and other constituents and improving the health of the watershed, while at the same time allowing for continued sustainable mining in the region.

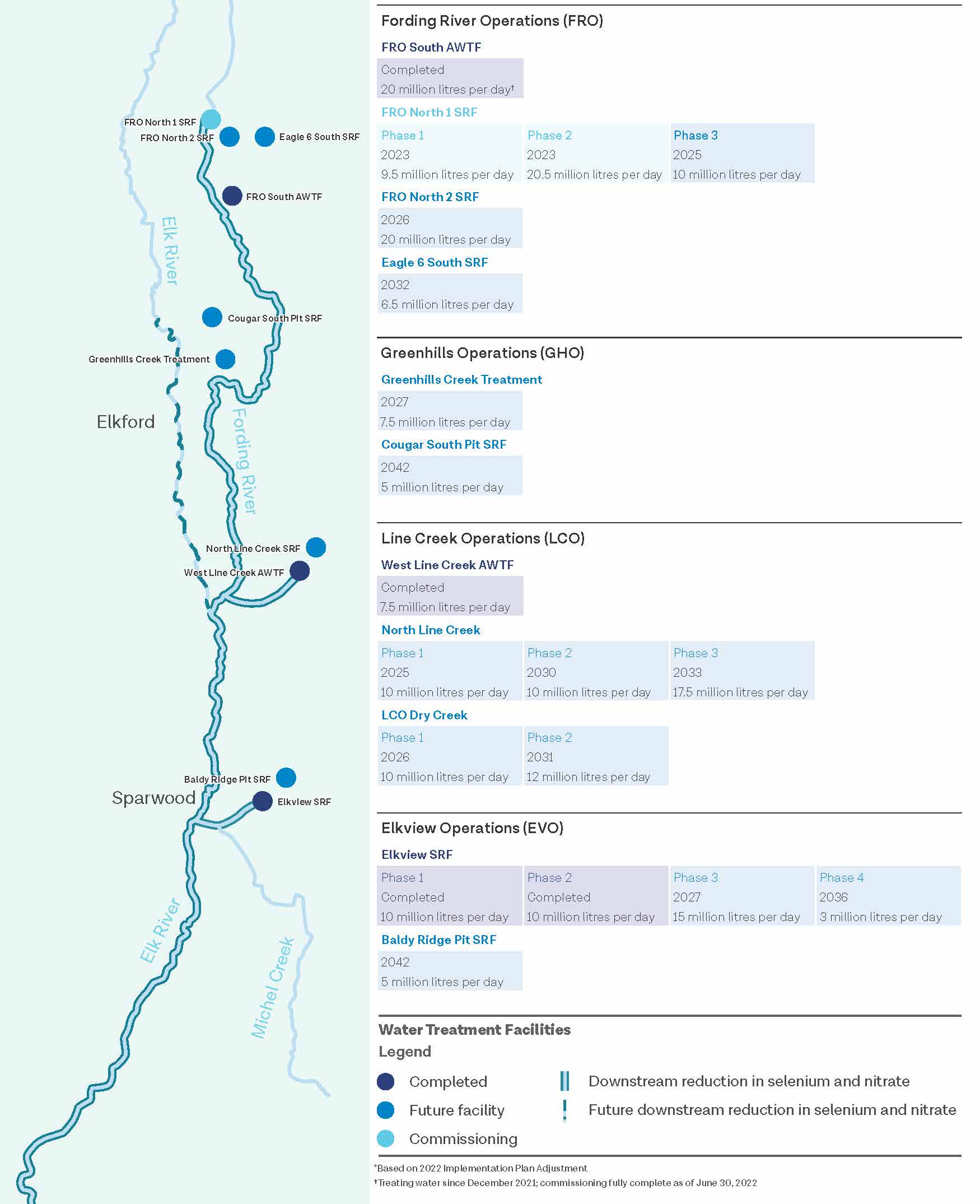

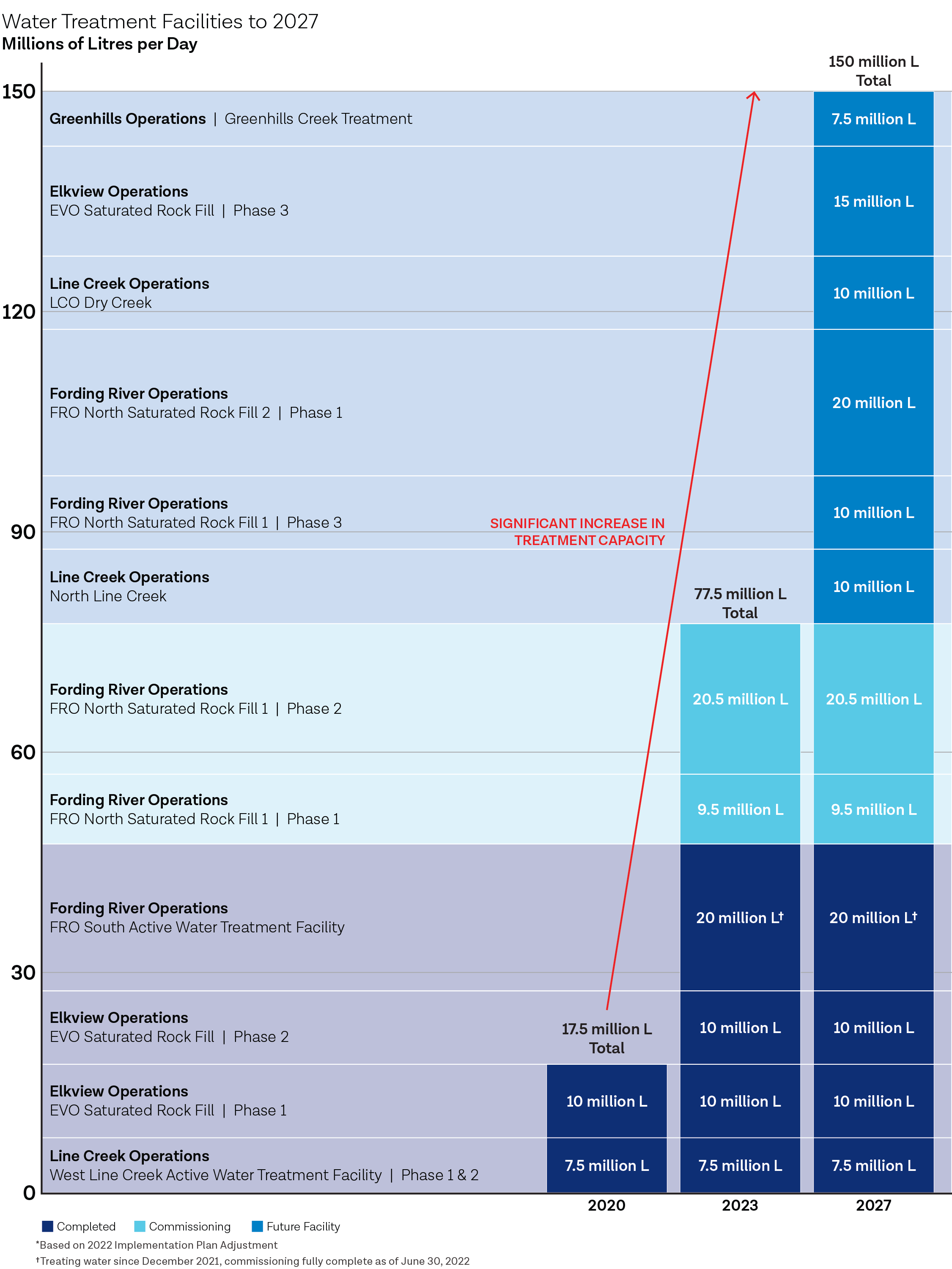

Teck has made significant progress implementing the Elk Valley Water Quality Plan. Water treatment facilities are operating now that are successfully improving water quality with more facilities planned and under construction.

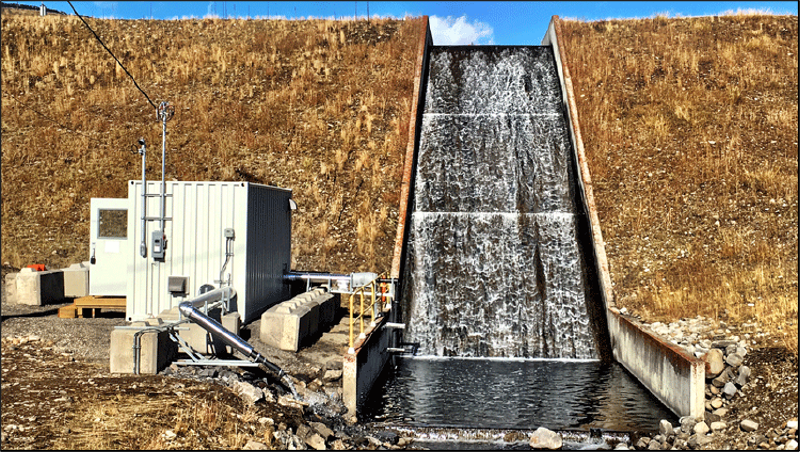

Our first water treatment facility is successfully treating 7.5 million litres of water per day at our Line Creek Operations and we are seeing reductions in selenium and nitrate concentrations downstream.

Our first water treatment facility is successfully treating 7.5 million litres of water per day at our Line Creek Operations and we are seeing reductions in selenium and nitrate concentrations downstream.

Our second water treatment facility, the Elkview Saturated Rock Fill, has been achieving near complete removal of selenium and nitrate from up to 10 million litres of water per day since 2018. In 2020, this Saturated Rock Fill was expanded and is now treating up to 20 million litres of water per day.

Our third water treatment facility, the Fording River South Water Treatment Facility, is now operating with capacity to treat up to 20 million litres of water per day.

Our fourth water treatment facility, the Fording River North Saturated Rock Fill, is currently in commissioning and will be ramping up to treat up to 30 million litres of water per day.

Teck’s water treatment facilities are achieving approximately 95% removal of selenium and nitrate from treated water. We expect further significant reductions of selenium and nitrate as additional facilities come online.

Teck now has constructed treatment capacity of 77.5 million litres of water per day, a four-fold increase from its treatment capacity in 2020. With this capacity, Teck expects to achieve one of the primary objectives of the Elk Valley Water Quality Plan: stabilizing and reducing the selenium trend in the valley.

Teck is implementing the Elk Valley Water Quality Plan (EVWQP), a long-term approach to address the management of selenium and other substances released by mining activities in the Elk Valley. Learn more about Teck’s progress implementing the Elk Valley Water Quality Plan

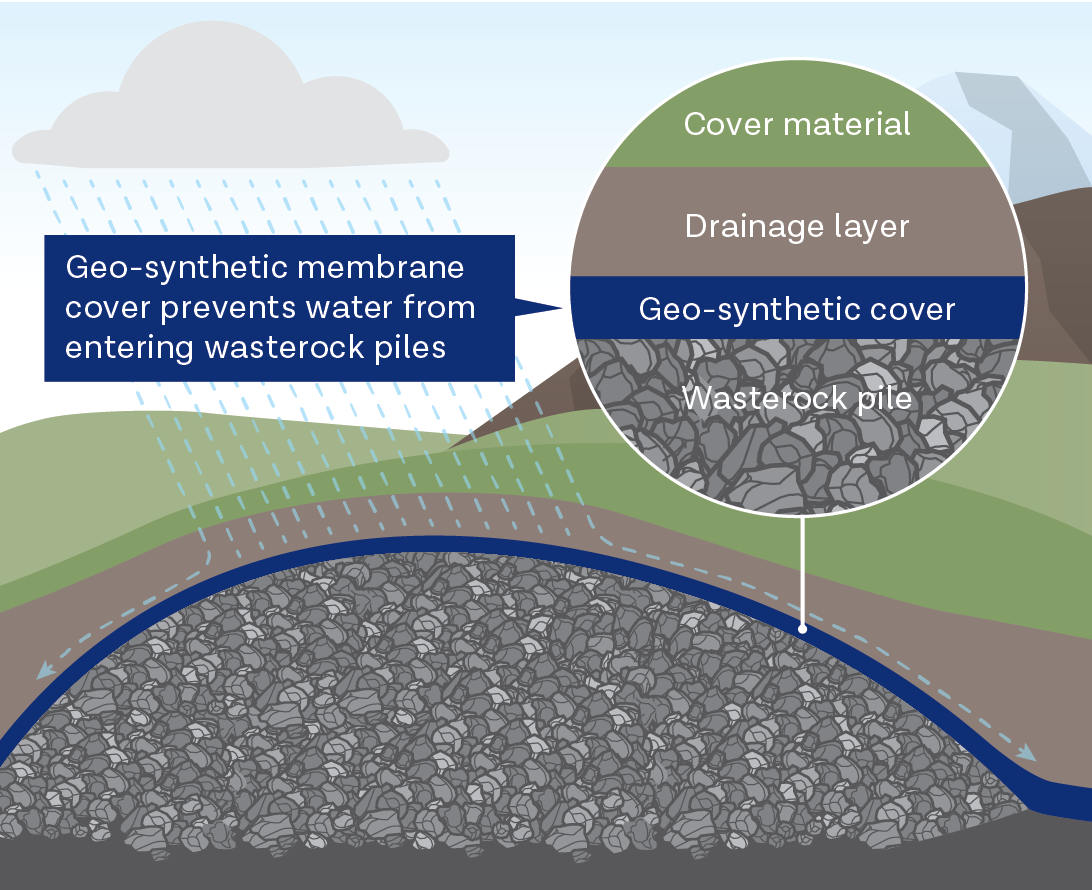

As part of the Elk Valley Water Quality Plan, Teck is researching and implementing methods to control selenium and nitrate release at the source.

Geo-synthetic covers are low permeability synthetic membrane barriers placed over top of a waste rock pile to reduce water percolating through waste rock and carrying selenium and nitrate into the watershed.

|

|

Geo-synthetic Cover Illustration |

Water Diversion Illustration |

Clean water diversions can reduce the volume of water affected by waste rock, thereby reducing the amount of water that needs to be treated.

Our comprehensive research and development program led to the development of a new nitrate prevention technique that uses liners that prevent explosives with nitrate from coming in contact with water. This technique has been applied across our operations in the Elk Valley and the majority of blast holes now utilize a liner that prevents nitrate from entering the watershed, protecting water quality.

Calcite occurs naturally, but its formation can be accelerated by runoff water from mines. It is not a human health concern, but excessive calcite build-up can change the characteristics of streambeds.

Teck has installed five treatment facilities that prevent any further formation of calcite in the watershed. Further to calcite precipitation mitigations, Teck is also advancing a pilot project to remediate calcite affected areas and enhance fish habitat.

We are conducting extensive studies and monitoring of water quality and aquatic health, which includes regular water quality monitoring at more than 130 locations across the Elk Valley.

Monitoring shows that selenium concentrations have been reduced downstream of our water treatment facilities at Line Creek and Elkview and we expect further significant reductions as the new Fording River facilities come online. Based on scientific understanding of selenium, the current concentrations are not expected to impact fish populations. Monitoring and research reports are available here.

The Elk Valley Water Quality Plan includes the adoption of new technologies and management approaches as further advancements in technology are achieved through this program.

Teck has undertaken a comprehensive research and development program that has led to the development of breakthrough technologies including:

Saturated Rock Fill technology to treat mine-impacted water that is achieving near complete removal of selenium.

The development of a new nitrate prevention technique that uses liners that prevent explosives with nitrate from coming in contact with water.

Teck has more than 25 research and development projects underway, including the advancement of smaller, in-situ water treatment facilities that can be built closer to where treatment is needed.

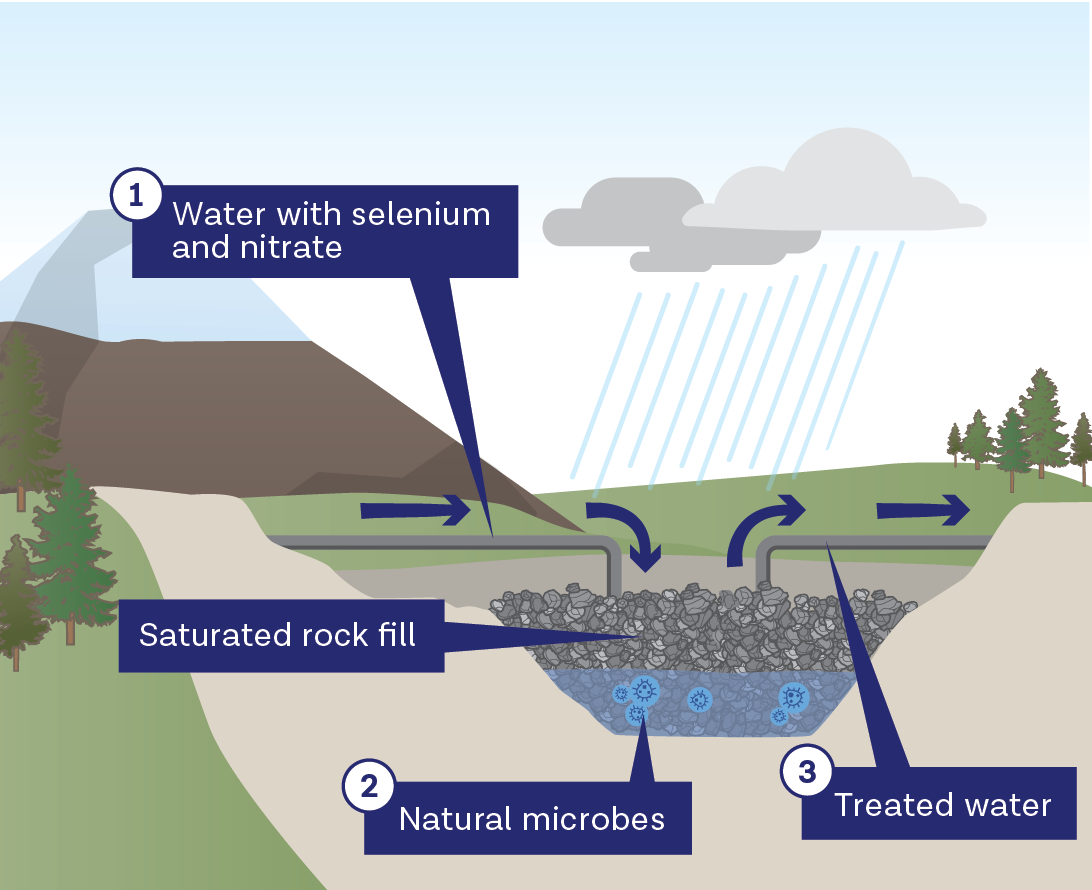

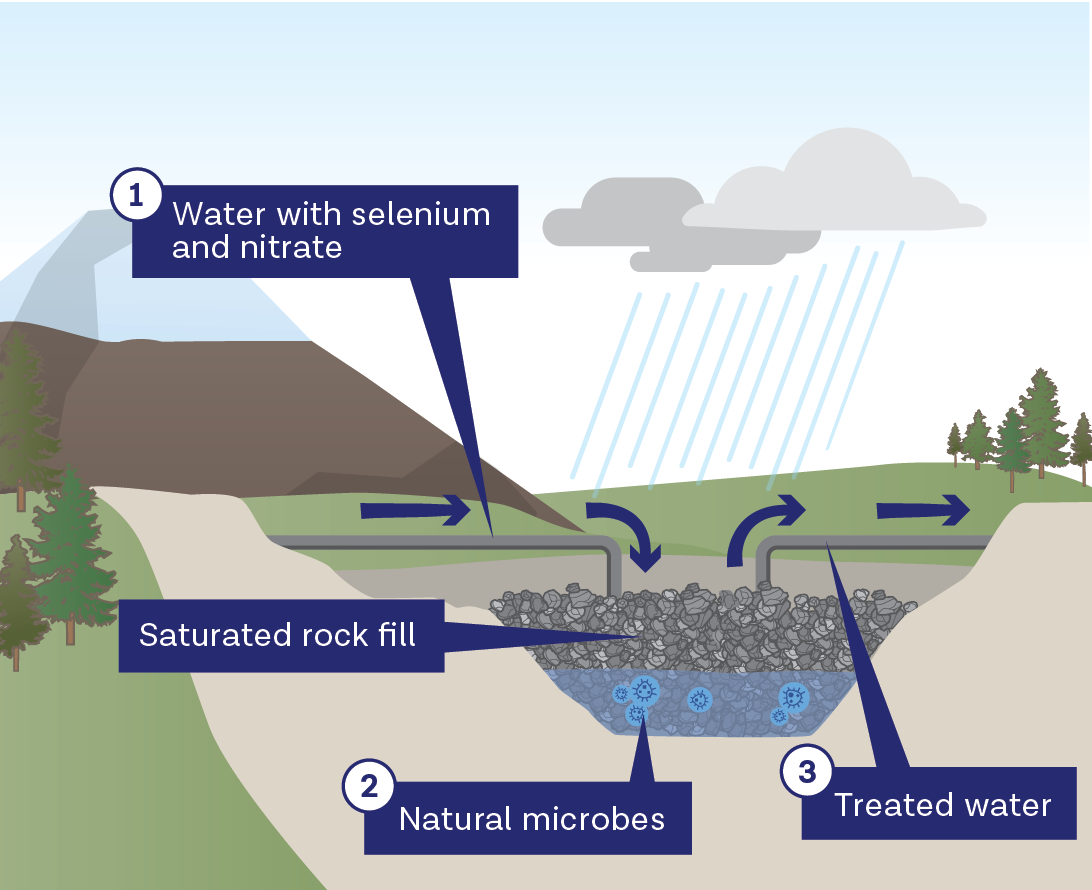

Saturated Rock Fills use naturally-occurring biological processes in former mining areas that have been backfilled with rock and saturated with water to remove selenium and nitrate:

Water for treatment is injected into the SRF

Natural bacteria convert dissolved forms of selenium into a solid form which remains securely stored in the SRF and nitrate to inert nitrogen gas which is safely released

Treated water is pumped out of the SRF and discharged

The benefits of SRF over other forms of water treatment:

Quicker to build and less complex to operate

Lower capital and operating costs

Treat larger volumes of water

Use less energy

Smaller environmental footprint

“Teck’s use of saturated rock fills to treat mine-affected water is leading-edge sustainable technology. Saturated rock fill is extremely effective at removing selenium and nitrate from mine affected water and improving water quality” — Dr. Lisa Kirk, an affiliate professor in Montana State University’s Department of Chemical and Biological Engineering, who helped develop saturated rock fill technology.

Overview of a Full-Scale Trial for Removal of Nitrate and Selenium from Mine-Influenced Water Using Saturated Rock Fill Technology

In collaboration with a number of research partners, Teck has developed and tested the effectiveness of saturated rock fill technology to treated mine-influenced water. This paper provides an overview of the design and operation of the SRF facility and shares results from the first 605 days of the full-scale trial, which took place at Teck’s Elkview Operations. Learn more

This biological treatment process removes nitrate and transforms selenium into a solid form through a process that includes the following steps:

Biological treatment to convert dissolved forms of selenium to solid form

Nitrate is converted into inert nitrogen gas and safely released

Solid selenium is extracted and safely disposed of in a secure onsite waste facility

Treated water is discharged

The Elk Valley Water Quality Plan includes the adoption of new technologies and management approaches as further advancements in technology are achieved through this program.

Teck has undertaken a comprehensive research and development program that has led to the development of breakthrough technologies including:

Saturated Rock Fill technology to treat mine-impacted water that is achieving near complete removal of selenium.

The development of a new nitrate prevention technique that uses liners that prevent explosives with nitrate from coming in contact with water.

Teck has more than 25 research and development projects underway, including the advancement of smaller, in-situ water treatment facilities that can be built closer to where treatment is needed.

Saturated Rock Fills use naturally-occurring biological processes in former mining areas that have been backfilled with rock and saturated with water to remove selenium and nitrate:

Water for treatment is injected into the SRF

Natural bacteria convert dissolved forms of selenium into a solid form which remains securely stored in the SRF and nitrate to inert nitrogen gas which is safely released

Treated water is pumped out of the SRF and discharged

The benefits of SRF over other forms of water treatment:

Quicker to build and less complex to operate

Lower capital and operating costs

Treat larger volumes of water

Use less energy

Smaller environmental footprint

“Teck’s use of saturated rock fills to treat mine-affected water is leading-edge sustainable technology. Saturated rock fill is extremely effective at removing selenium and nitrate from mine affected water and improving water quality” — Dr. Lisa Kirk, an affiliate professor in Montana State University’s Department of Chemical and Biological Engineering, who helped develop saturated rock fill technology.

Overview of a Full-Scale Trial for Removal of Nitrate and Selenium from Mine-Influenced Water Using Saturated Rock Fill Technology

In collaboration with a number of research partners, Teck has developed and tested the effectiveness of saturated rock fill technology to treated mine-influenced water. This paper provides an overview of the design and operation of the SRF facility and shares results from the first 605 days of the full-scale trial, which took place at Teck’s Elkview Operations. Learn more

This biological treatment process removes nitrate and transforms selenium into a solid form through a process that includes the following steps:

Biological treatment to convert dissolved forms of selenium to solid form

Nitrate is converted into inert nitrogen gas and safely released

Solid selenium is extracted and safely disposed of in a secure onsite waste facility

Treated water is discharged

At Teck, we are working to achieve our vision of a net positive impact on biodiversity in areas affected by our activities.

Teck Response to United States Geological Survey Loading Study - December 2023

Letter to the Editor of the New York Times: Tracing Mining’s Threat to U.S. Water - July 12, 2023

Public Notice: Regarding Potable Water Use in The Elk Valley - March 2023

Elk Valley Water Quality Virtual Open House Presentation - November 23, 2022

Public Notice: Environmental Protection Notice - Application for Permit Amendment - September 2022

Public Notice: Environmental Protection Notice - Notice of Filing - August 2022

Elk Valley Water Quality Plan 2022 Implementation Plan Adjustment Overview - July 2022

Letter to the Editor: Recent data spell trouble for Koocanusa Fish – March 31, 2022

Water Quality in the Koocanusa Reservoir - March 2022

Public Notification Regarding Potable Water Use in the Elk Valley - March 2022

Public Notification Fording River Operations Eagle 4 Saturated Rock Fill - June 2021

News Release - Teck Resolves Fisheries Act Charges - March 2021

Public Notification Regarding Potable Water Use in the Elk Valley - March 2021

New Water Quality Measures in the Elk Valley - October 29, 2020

Environment and Climate Change Canada - New Water Quality Measures in the Elk Valley

Public Notification: Active Water Treatment Facility - Landfill - January 2020

Public Notification: Active Water Treatment Facility - South - January 2020

Environmental Monitoring Committee 2019 Public Report

Letter to the Editor of the Flathead Beacon: Elk Valley Water Quality Plan Progress – June 17, 2019

Letter to the Editor of the Fernie Free Press: EVWQP Implementation Plan Adjustment – April 8, 2019

Elk Valley Water Quality Plan - 2019 Implementation Plan Adjustment - February 2019

Teck Reaches Milestone in Water Quality Research Program - October 15, 2018

West Line Creek Active Water Treatment Facility Restarts - October 4, 2018

Results of ongoing water quality research and monitoring undertaken as part of the Elk Valley Water Quality Plan.

An economic study by the BC Chamber of Commerce, the United Steelworkers and Teck, “Economic Contribution Analysis of Mining Operations in the Elk Valley” shows Teck’s steelmaking coal operations in B.C.’s Elk Valley make up 80% of Gross Domestic Product (GDP) for the region, sustain more than 30,000 jobs and contribute $1.5 billion in revenues annually to three levels of government. The study was produced by Deloitte LLP.

Teck Resources Limited

Suite 3300, Bentall 5

550 Burrard Street

Vancouver, B.C.

Canada V6C 0B3

t: 604.699.4000

f: 604.699.4750