— Mariet Minchev, Project Manager for the Mobile Proximity Detection Project

Technology and innovation are not only critical to improving productivity, but to supporting Teck’s goal of eliminating serious injuries. Collision and proximity detection has reduced the overall risk associated with vehicle interactions and helped to contribute to a 38% reduction in high-potential incident frequency in 2021 compared to the previous year.

Heavy equipment including haul trucks, loaders, dozers, auxiliary and light vehicles all work together at a mine site to make operations happen. Collisions between these vehicles can result in serious injuries. Mobile Proximity Detection technology warns drivers of their proximity to other vehicles and obstacles to prevent collisions occurring. To date, this technology has been successfully installed in light and heavy vehicles at six of Teck’s sites: Line Creek Operations, Greenhills Operations and Fording River Operations in Canada, Red Dog Operations in Alaska and Carmen de Andacollo and Quebrada Blanca in Chile.

Mobile Proximity Detection system is made up of three parts: an antenna is installed on the outside of the truck to enable 360-degree visibility and signal, a computer in the cabin to process the signals and store data, and an LED screen that sits on the dashboard to show any warnings to the driver. The system can be configured to map different areas on the site, including any fixed hazards, overhead powerlines, higher-risk areas of collision and speed limits. Depending on proximity to other vehicles, the driver is alerted through various signals on an LED screen in the cabin. When vehicles are at risk of having a collision, a sound will go off in the cabin as a warning.

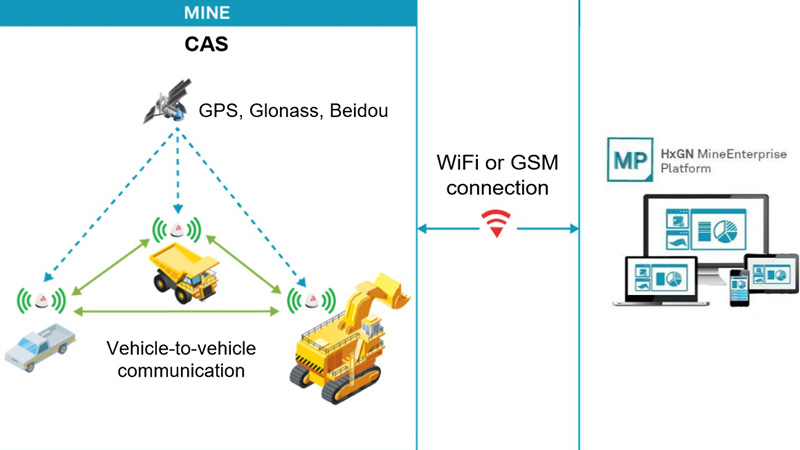

Mobile Proximity Detection enables vehicle-to-vehicle communication to alert drivers when they are at risk of collision, using a Collision Avoidance System (CAS). Over 600 CAS have been installed in heavy and light vehicles across Teck’s operations.

Enabling new risk and safety monitoring capabilities, the system connects through a Wi-Fi connection to report data. As a result of this data, Teck has access to detailed trend reports on critical risks to support more safety-informed decisions in our operations and increase transparency around collision risks.

The next step for this innovative system is installation in additional pit equipment including loaders, dozers and buses in 2022.