The successful delivery of QB2 depends on a unified team with a shared vision of building Teck’s mine of the future.

With a project the size and scale of QB2, significant planning is required to safely mobilize the workforce across the six construction areas that span 200 kilometres and 10,000 square kilometres. That’s why Karl Hroza, Project Director, kicked off the first of many one-team alignment meetings and a series of workshops for the various project areas and supporting functions. QB2’s one-project, one-team approach is aligning all aspects of the project to set a new standard for project delivery.

Construction Begins at the Tailings Management Facility

In May of this year, the Teck QB Mine Fleet successfully completed the main haul road required to support the construction of the tailings management facility (TMF). Construction to develop the TMF is now underway, including the lateral access roads to the starter dam and valley drains. The first deliveries of rock for the TMF cofferdam were received by Teck’s construction and management partners, Excon, Bechtel and Golder, who are responsible for compacting the materials. This process involves building 1.2 metre individual layers until a height of 120 vertical metres is reached. This is currently expected to be completed in the summer of 2021, in order to start filling the pond to support commissioning of Line 1 of the Concentrator.

Focusing on Health and Safety

With construction well underway and resources increasing daily, the risks related to the interactions between heavy-duty equipment and light vehicles highlights the importance of maintaining a controlled, safe operation. Careful planning on the part of Teck and Bechtel continues to be a key focus and is essential for the machinery to safely transport and unload material.

Pipeline Area Work Advances

While activity related to the overall facility advances, construction on key elements of the pipeline area are also underway with mass earthworks and development of platforms for pumping stations No. 2 and No. 5. These are two of the five pumping stations that will supply desalinated water to the mine.

The first of two pipeline camps, which will accommodate over 3,000 construction workers, is now in service.

The delivery of pipe segments continues with over 25 truck transports per day from the Port of Angamos. More than 10,000 units are expected to arrive before the end of the year. Techint, the pipeline contractor for QB2, will be responsible for constructing the pipeline and has mobilized to three work fronts on the project.

Growing the Local Economy

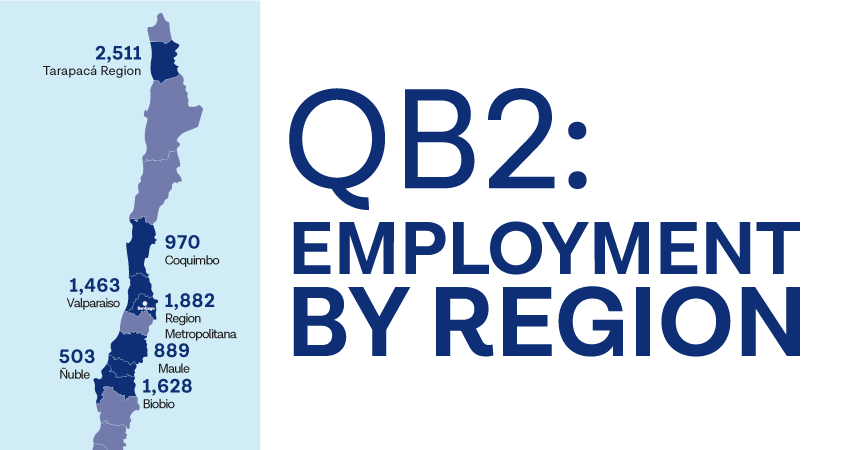

Tapping into the local resources and workforce is key to our sustainability strategy and is an important requirement for all contractors engaged in the construction of QB2. By sourcing materials locally, working with local vendors and employing construction workers from the region, we’re helping to grow Tarapacá and Chile’s economy while generating value for the communities surrounding the project areas.

As of September, QB2 purchased a total of USD $21 million of goods from local suppliers, and this is set to grow significantly over the course of the project. At the same time, QB2 has employed nearly 2,500 local construction/service workers from the Tarapacá Region.

Supporting gender diversity of the QB2 workforce is another important focus in our efforts to grow the local economy. Women currently make up 9% of the construction workforce, which is slightly above the industry average of 8.5%3. While this is positive, we know there is still much more we can do to advance the inclusion of women at QB2 and across our operations in Chile. Our ongoing work through Women in Teck, a support network for women, is just one way we are driving gender diversity. You can learn more about our efforts at www.teck.com/responsibility