Throughout our history, Teck has changed the way the mining industry operates by developing new technologies and the introduction of new processes. Here are just a few examples of how…

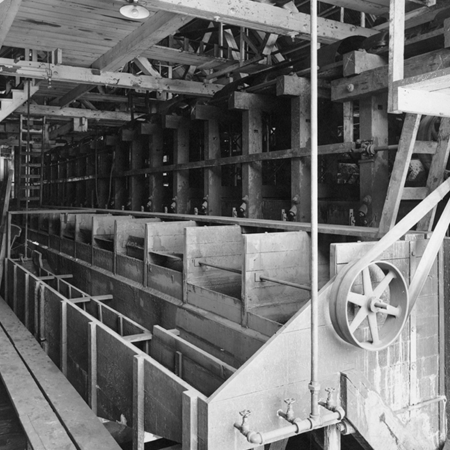

Differential Froth Flotation

In 1917, we helped to develop the method of mineral processing known as differential froth flotation, which significantly improved mineral recovery, increased the efficiency of our operations and became an industry standard. The technology allowed separate recovery of lead and zinc concentrates. This technology has become the industry standard used around the world for various types of orebodies.

Aeromagnetic Surveying

In 1946, Dr. Norman Keevil Sr. introduced aeromagnetic surveys to Canada, based on technology developed during World War II to detect submarines. Using a geophysical technique called Self Potential, Dr. Keevil and his associates found the high-grade copper deposit that became the Temagami Mine. The effect of this discovery completely altered the face of mining exploration, and the technology is still widely used today.

Water Treatment

In 1979, at our Sullivan Mine, we pioneered a groundbreaking water treatment technology known as high-density sludge water treatment, and installed one of the first operating plants in the world to treat acidic mine drainage water. This technology is now widely used in the industry, especially for the treatment of mine-affected waters.

Drill Navigation System

In 1994, the Aquila drill navigation system was developed at Fording River Operations. As the first deployment of high-precision GPS, it allowed operators to navigate within +/- 10 cm, regardless of weather and visibility. The highly improved accuracy enabled smoother benches and blasted to a constant elevation and more consistent fragmentation. Combined with rock recognition, this navigation system improved blast designs and recovery. Today, Aquila, or Terrain as it is now known, is still the industry standard.

The CESL Process

In 1994 at our CESL facility, a specialized hydrometallurgical process known as the CESL Process was developed and patented. The process is capable of unlocking value from large, long-life copper sulphide resources that produce concentrates with high levels of impurity elements, such as arsenic, while minimizing the environmental costs of doing so. The CESL Process is also applicable to bulk, lower grade or impurity challenged copper-nickel sulphide concentrates that would otherwise be problematic and uneconomic to process using traditional technologies. Teck is actively pursuing opportunities to take advantage of this proprietary and commercial-ready technology.

Water Management

Teck is taking action to address the challenge of substances related to mining in water, such as selenium, and to protect the health of the Elk River watershed in B.C., through our Elk Valley Water Quality Plan. As part of this work, in 2016, we commissioned the West Line Creek Water Treatment Facility, which is designed to remove selenium, nitrate and other elements, using a biological water treatment process that relies on micro-organisms to convert selenium to its particulate form and then remove it through filtration. Construction is also underway of the Active Water Treatment Facility at our Fording River Operations, which will use the same treatment process and recent additional design enhancements as our West Line Creek facility.