When trying to accomplish something really big, effort can be everything. That holds true for mining, where the effort needed to dig is a major factor in cost, time and efficiency. However, directly measuring that effort has been all but impossible, until now.

Using sensors mounted on shovels, Teck developed a groundbreaking method to measure the ease or difficulty of the digging conditions for a given shovel, and we are using that measurement to continuously improve performance at our mines.

This measure – called ‘digability’ – is analyzed to determine the optimal balance in our blasting. Using the digability measure helps to reduce explosive use, blasting costs, and equipment wear. It also helps to maximize the productivity of our shovels, reducing costs and improving environmental performance.

Digability was first piloted at Teck’s Elkview Operations in British Columbia and was proven to reduce explosives consumption and therefore nitrates – a component in blasting – by 9%. This technology is now being implemented at additional Teck operations and will be expanded further through 2018.

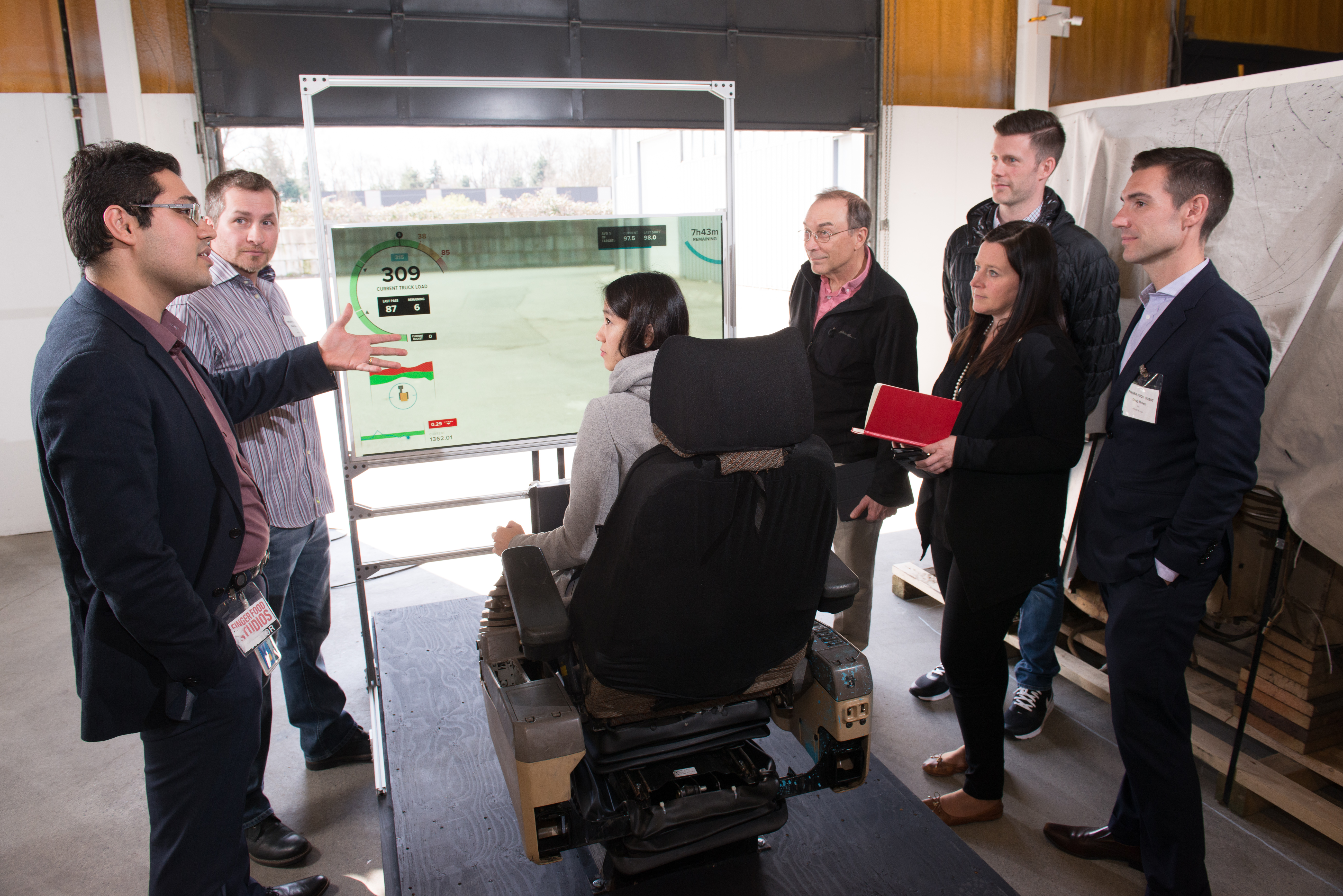

Teck is also pioneering new methods to provide key operating data to shovel operators in real-time using a heads up display. Like the cockpit of a fighter jet, the heads up display will appear on the glass in front of the operator and show operational information to guide their work and maximize efficiency.

We’re putting ideas like digability and heads up displays to work across our operations. Learn more about our approach to innovation and technology.